Japan’s Wooden Satellites: How Engineers Are Reinventing Space Technology With Timber

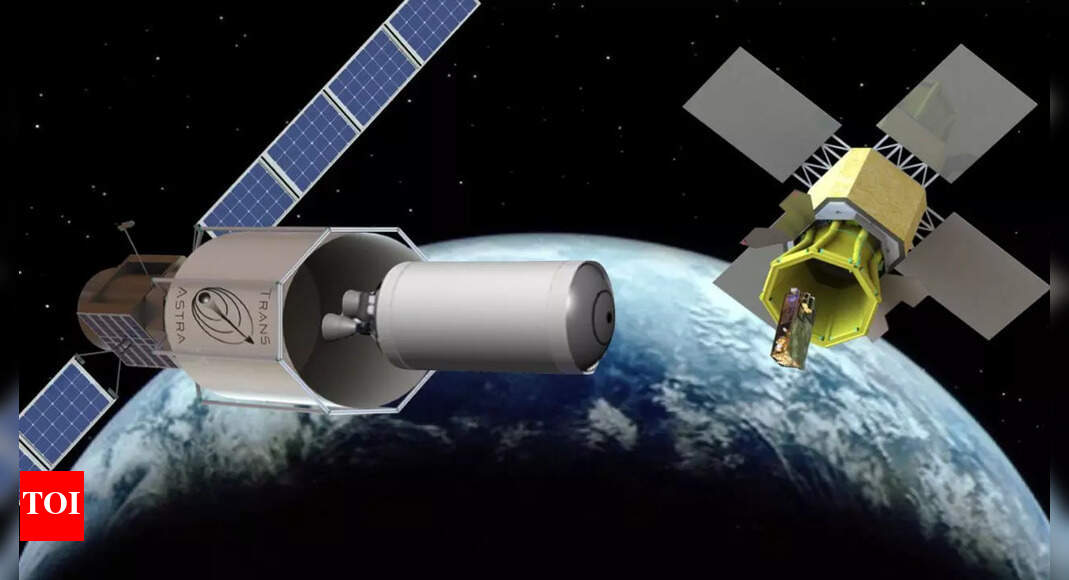

When you picture a satellite orbiting Earth, you probably imagine something metallic and high-tech—aluminum panels, titanium frames, maybe a few carbon-fiber components. The very last material you’d expect to see floating 400 kilometers above Earth is… wood.

Yet that’s exactly what a team of engineers from Kyoto University and Sumitomo Forestry in Japan have set out to test with their groundbreaking project LignoSat, the world’s first wooden satellite. As strange as it sounds, this experiment may open the door to a cleaner, more sustainable future for space exploration.

Why Wood? The Surprisingly Logical Answer

At first glance, using wood in space feels almost whimsical, like something out of steampunk fiction. But the logic behind it is solid—and surprisingly practical.

1. It reduces space pollution

Humanity has launched thousands of satellites, and that number is skyrocketing as private companies race to build satellite constellations. Eventually, all these satellites deorbit and burn up in the atmosphere. Metal satellites leave behind particles—particularly aluminum oxide—that linger in the upper atmosphere and may impact climate and ozone chemistry.

A wooden satellite, on the other hand, burns up almost completely and leaves minimal harmful residue. It essentially returns to the atmosphere as ash rather than metallic dust.

2. Wood behaves better in space than you’d think

On Earth, wood warps, cracks, rots, or gets eaten by bugs. But in space?

None of that exists.

There’s no moisture, no oxygen, no bacteria, no termites. Wood becomes surprisingly stable and could even outperform some metals in terms of thermal behavior. The Japanese team discovered that wood doesn’t burn or char in vacuum conditions—even at extreme temperature cycles.

3. It’s lightweight and renewable

Satellites are all about weight reduction. Every gram saved reduces launch costs. Wood is naturally lightweight and grows back—something you can’t say about titanium or aluminum.

In other words, wood isn’t just “good enough.”

It may actually offer unique advantages in certain missions.

Meet LignoSat: A Satellite Crafted Like a Work of Art

LignoSat isn’t just made of any wood. It uses magnolia wood, known in Japan as hōnoki, a traditional material used in everything from temple crafts to samurai sword sheaths. Magnolia is valued for its softness, dimensional stability, and clean grain, making it ideal for precise engineering.

But here’s the coolest part:

- The wooden components were assembled using a traditional Japanese joinery technique called “sashimono.”

- No screws.

- No glue.

- Just perfectly interlocking joints handcrafted with microscopic precision.

This isn’t just engineering—it’s craftsmanship.

Inside, of course, the satellite is packed with the usual modern electronics: solar panels, onboard computers, and communications equipment. Wood is used for the exterior structure, acting as the body and protective casing.

The satellite is roughly the size of a coffee mug—about 10×10×10 centimeters—and weighs under a kilogram. It’s small, but it represents a completely new category of aerospace materials.

What Are Engineers Testing?

LignoSat’s mission isn’t about taking fancy photos or mapping climate patterns. It’s a science experiment focused on wooden material performance in orbit. Engineers want to learn:

How does wood handle extreme temperatures?

In low Earth orbit, a satellite can swing from –100°C in the shade to +100°C in direct sunlight. The repeated thermal cycling can cause materials to expand and contract—possibly cracking. Engineers are monitoring whether magnolia wood can withstand these stresses.

How does it handle radiation?

Space radiation is intense. Wood may actually absorb certain radiation types better than thin metal walls. Understanding this could influence future spacecraft shielding designs.

Does it deteriorate in vacuum?

Without moisture or oxygen, wood behaves differently. The team wants to analyze the microscopic structure of the wooden panels after the mission.

What happens when it burns up on reentry?

The whole point is environmental benefit, so scientists are tracking how cleanly the wood incinerates when the satellite eventually returns to Earth.

A Potential Shift in Space Technology

If this experiment works, wooden materials could become a standard option for small satellites—especially CubeSats used by universities, researchers, and startups. These satellites are cheap to build, quick to deploy, and perfect for testing new ideas.

But why stop there?

Future ideas include:

- wooden components for lunar or Martian habitats

- wooden housings for sensors or instruments

- hybrid satellites combining wood with composites

- low-cost, biodegradable satellite fleets for short-term missions

The concept might even shape how future space agencies think about sustainability. As one Kyoto University researcher joked, “Maybe in 30 years, people will look up at the night sky knowing some of those satellites were once trees.”

A Blend of Tradition and Innovation

LignoSat represents something rare in modern technology:

a fusion of ancient craftsmanship and cutting-edge engineering.

Japan is well known for honoring its past while driving technological innovation forward, and this satellite embodies that spirit perfectly. It’s poetic, practical, environmentally conscious, and just a little bit quirky—in the best possible way.

Whether wooden satellites become commonplace or remain a niche experiment, LignoSat has already made history. It challenges our assumptions about what materials belong in space and reminds us that sometimes the future of technology begins with something as simple, elegant, and renewable as wood.

link